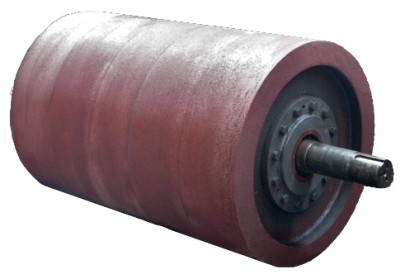

The renewing of worn friction linings was yesterday –

today POLYdrive kodiak DRUMS are used for conveying!

The revolutionary polymer coating allows for an easy conveyance of bulk material even when other friction linings would have long given up especially in wet conditions.

High coeffcients of friction, extremely acid resistance and its

anti-magnetic behavior make the POLYdrive kodiak DRUMS the first choice of

modern bulk material goods conveyance.

Whether drive drums in solid body ( PVA) or tension design (

PVA) or tension design ( PSA), you will

always be served with the highest possible level of reliability and tractive

power.

PSA), you will

always be served with the highest possible level of reliability and tractive

power.

Our knowhow allows us to offer an upgrade of your existing drums applying our

polymer casting technology ( PRA). The drum body delivered is cast onto the

closest possible drum diameter (see flyer).

PRA). The drum body delivered is cast onto the

closest possible drum diameter (see flyer).

- Shaft executed in S355J2R (St52.3) or stainless steel.

- Individual production based on customer drawings.

- High quality shaft-hub-connection with locking devices (e.g.System – Bikon).

The importance of the friction coefficient!

The friction coefficient of the drive barrel, the wrap angle and the pre-tensioning all determine the transmission of tangential force.

The dimensions of the barrel, the pre-tensioning and diverse other equipment depend primarily on the friction coefficient.

In practice, the friction coefficient fluctuates widely and depends on:

- Type and surface texture of the barrel

- Lubricants between the belt and the barrel such as water and grease

- Temperature

- Bearing pressure

- Slip velocity and sliding speed

POLYdrive kodiak DRUMS demonstrates its strength in these areas, even with remarkably low band tension!